A Hotel’s Cooling Crisis

Mr. Reddy, the facility manager of a hotel in Secunderabad was in a tough spot.

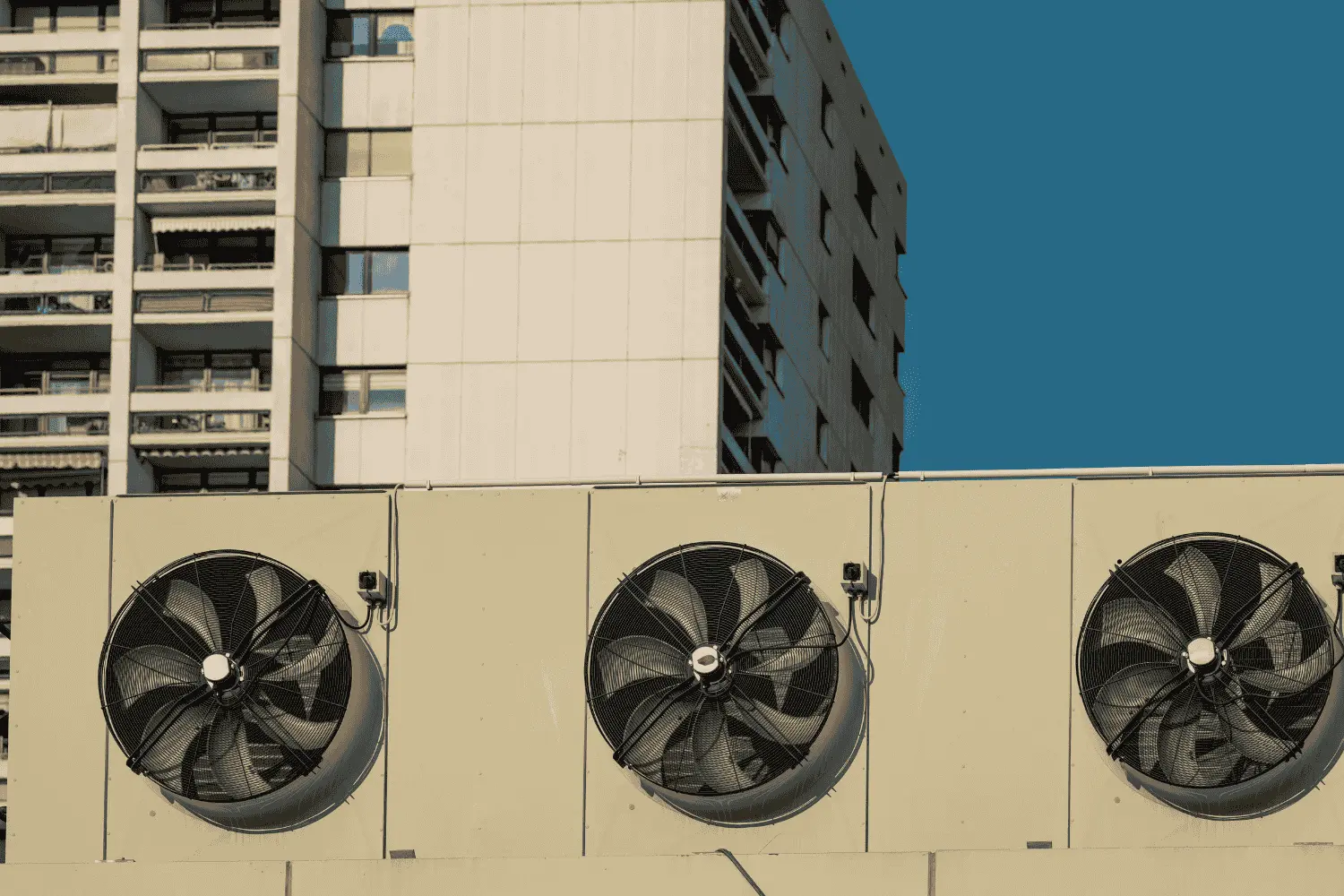

His guests expected a comfortable stay, which meant 24/7 air conditioning year-round. But behind-the-scenes in the basement, the hotel’s old cooling systems (chillers, pumps, cooling towers) were struggling to deliver – resulting in astronomical energy costs.

The cooling system was outdated, inefficient, and expensive—one of their active chillers had been installed before 2010, back when technologies we take for granted today (like WhatsApp) didn’t even exist!

“Every month, the electricity bill was a shock,” Mr. Reddy recalls. “We knew we needed to upgrade our cooling infrastructure, but investing crores in new chillers just wasn’t an option.”

That’s when Mr. Reddy and his team found Energeia in 2024. Our E-Chill ESCO Model was perfect for his needs – it meant he could get a state-of-the-art chiller upgrade with zero upfront cost.

“I couldn’t believe it at first. No Capex, lower bills, and they’d even take care of maintenance? It felt too good to be true.”

But Energeia delivered on every promise.

Key Stats

Annual Monetary Savings

Annual Energy Savings

CO₂ Emission Reduction

Customer Overview

A 20 year hotel in Secunderabad, Telangana

- Location: Secunderabad, Telangana (India)

- Facility: Multi-story hotel with significant cooling needs for guest comfort and operations

- Existing Cooling System:

- 225 TR water-cooled chiller

- 130 TR water-cooled chiller

- 3 primary pumps

- 3 condenser pumps

- 3 cooling towers

The Challenge

Rising Costs, No Budget for Upgrades

- Inefficient Energy Usage – The system consumed 6,53,747 kWh annually, with an inefficiency of 1.58 kW/TR.

- Aging Equipment – One chiller was non-functional, making the hotel vulnerable to breakdowns.

- Constant Maintenance Hassles – The pumps ran at fixed speeds, leading to wasted energy and higher wear and tear.

- Zero Budget for New Systems – The hotel needed an energy solution without major capital investment.

The Solution

Energeia’s E-Chill Zero-Capex Financing Model

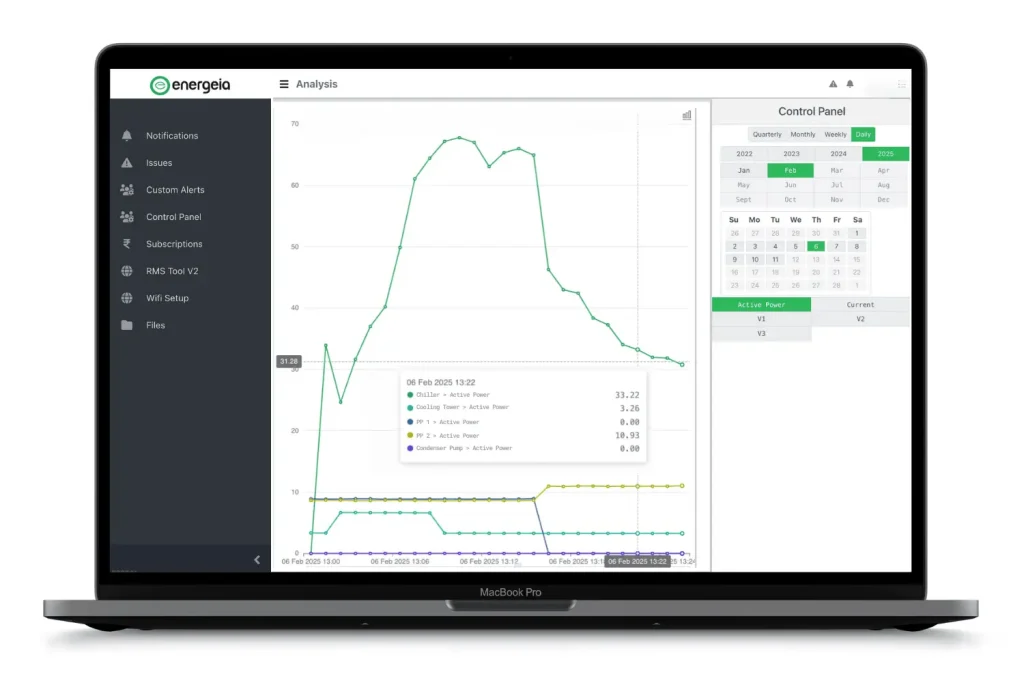

Energeia’s team started by conducting a real-time IoT-based chiller audit using our energy monitoring system (EMS). Our BEE-certified energy managers looked through the data to baseline energy consumption, cooling demand, and efficiency losses.

We presented a host of solutions with potential ROI calculations to Mr. Reddy. Together, we decided that the best solution was a high-efficiency chiller replacement + intelligent system optimization – financed through Energeia’s Shared-Savings ESCO Model.

Step 1: High-Efficiency Chiller Replacement

We replaced the old non-operational chiller with a state-of-the-art water-cooled chiller with factory-fitted Variable Frequency Drives (VFDs).

Step 2: Smart Pump & Cooling Tower Optimization

- We upgraded pumps with VFDs to dynamically adjust to cooling demand.

- We installed an automatic tube cleaning system to maintain long-term efficiency.

- We replaced the old cooling towers with new energy-efficient, low-approach cooling towers to improve overall system performance.

Step 3: IoT-Based Performance Monitoring & Maintenance

- We installed real-time sensors, flow meters, and energy tracking to make sure the cooling systems performed at peak efficiency every minute of the day.

- We guaranteed the chiller’s performance for 6 years, absorbing all operational risks.

The ESCO Advantage

Zero Capex, Zero Worries

- No Capital Expenditure – Energeia financed, installed, and maintained the new chiller.

- Risk-Free Performance Guarantee – Energeia bought the new chiller and absorbed all financial risks.

- No Downtime – A backup chiller ensured uninterrupted cooling during installation and maintenance.

Curious about ESCOs? Learn more here.

| Metric | Before (Old Chiller) | After (New System) | Improvement |

|---|---|---|---|

| HVAC Plant Efficiency | 1.58 kW/TR | 0.81 kW/TR | ⬆️ 48% More Efficient |

| Annual Energy Use | 6,53,747 kWh | 3,34,780 kWh | ⬇️ 48% Reduction |

Like this hotel, you can reduce your energy costs without investing a single rupee upfront. Click here to see how we replaced another chiller for a leading pharmaceutical factory using our Zero-Capex ESCO model.

📞 Book a Free Energy Appraisal Today: +91 9319271849

✉️ Email: sales@energeia.in