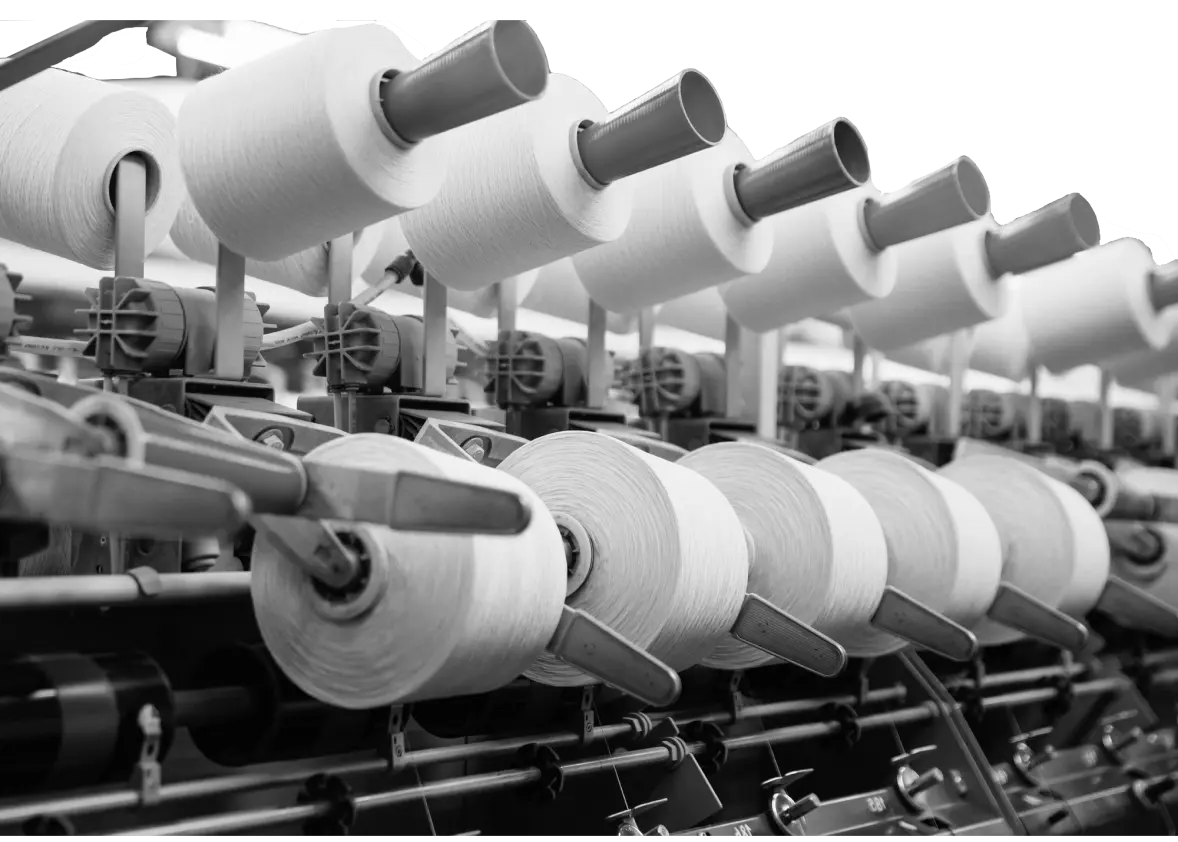

Textile

Spin Energy Cost Savings into Every Thread

Reduce energy waste and modernize your factory equipment with zero upfront investment

Start Saving Today

Trusted by 500+ Businesses

The Opportunity

Integrate Quick Savings with Energy Efficient Production

1

Cut Energy Costs

Lower consumption in energy-intensive processes like dyeing and spinning for more profitable output.

2

Meet Emission Standards

Stay compliant and sustainable with cutting-edge energy technologies that meet international standards.

3

IoT Monitoring

Continuously monitor energy consumption in real-time across textile processes to identify wastage patterns.

4

Personalized Solutions

Get tailor-made solutions for your manufacturing needs, supported by our expertise in complex textile processes.

Our Solutions

- Audit Services

- Utility Optimization

- Consulting Services

- Dual Fuel Kits

Comprehensive Energy Audit

Deep dive into your plant’s energy use to uncover waste and improve processes.

Compressed Air Audit

Detect leaks and inefficiencies in your air systems to reduce energy costs.

Steam Audit

Evaluate and enhance steam usage in textile processes, improving thermal efficiency.

Renewable Energy Feasibility Audit

Explore integrating solar energy solutions into high-energy-consuming processes.

E-Air

Maximize the efficiency of your air compressor plant with minimal upfront investment.

E-Chill

Modernize chiller and cooling systems to reduce energy usage and costs, while maintaining optimal conditions.

E-Heat

Boost heating efficiency of boilers, furnaces and hot water generators to unlock energy cost savings.

Project Implementation

Receive guidance tailored to textile manufacturing, optimizing energy usage and upgrading systems to reduce costs.

Financial Consulting

Leverage the benefits of grants and incentives to maximize your energy investments and get measurable cost savings.

Compliance Navigation

Stay on top of changing regulations, boosting sustainability with our detailed reports and 5-year strategy.

Renewable Energy

Integrate renewable energy solutions to power your textile plant and reduce grid reliance for consistent output.

Sustainability Training

Train your team in modern energy-efficient practices, ensuring long-term operational success as a competitive edge.

Diesel to Gas Conversion

Automatically switch between diesel and natural gas for uninterrupted generator performance and high energy efficiency.